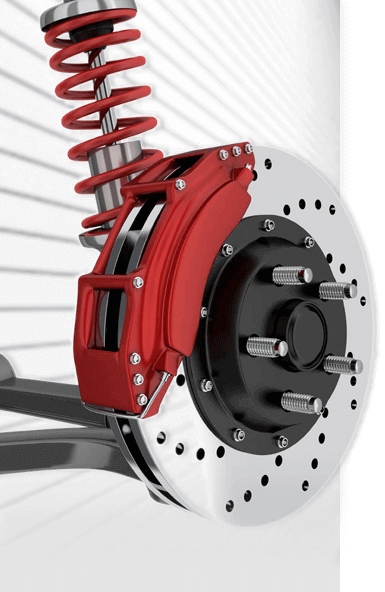

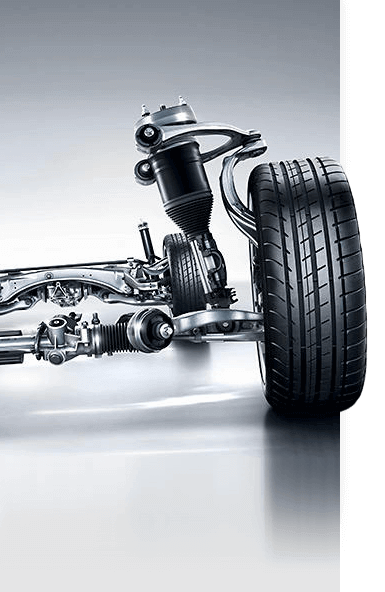

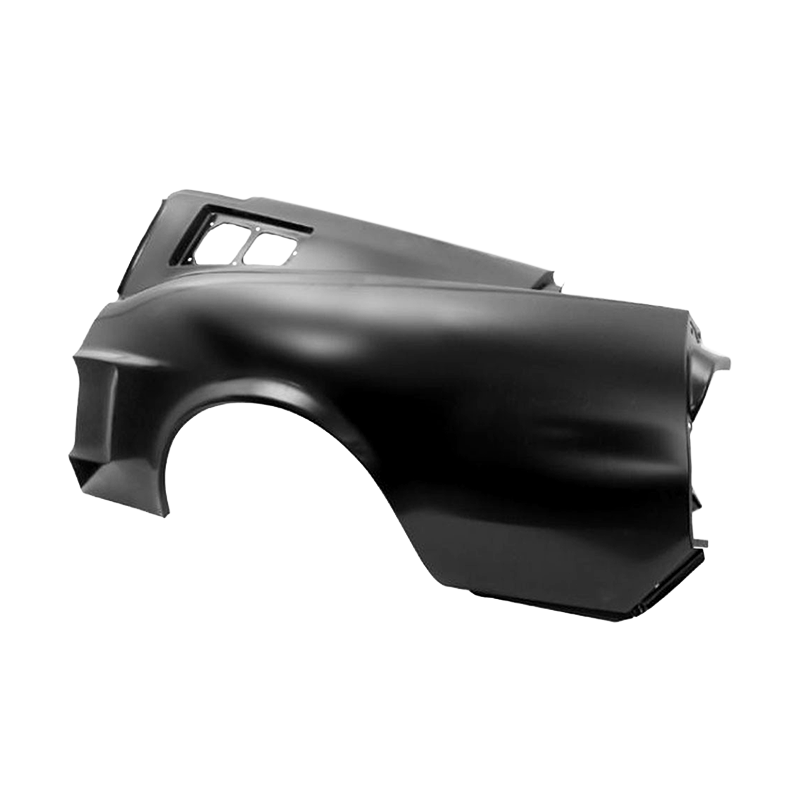

A three-piece wheel consists of three distinct parts, a forged center, spun aluminum inner barrel and a spun aluminum outer barrel (lip). These three components are sealed together creating the final product. So, what’s so special about that? This manufacturing process allows for an almost infinite selection of fitment configurations. Because these wheels are almost always custom orders, they can be designed to accommodate any modification to suspension, brake size, bolt pattern etc. to ensure the wheel is a perfect fit for a specific vehicle. That’s an important consideration for any vehicle but critical for high-performance rides.

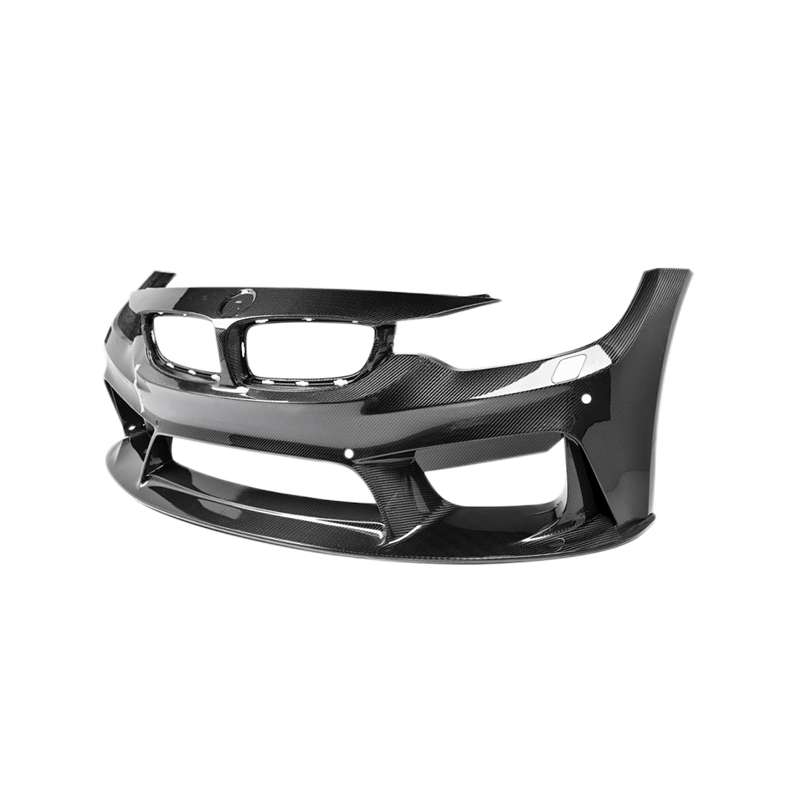

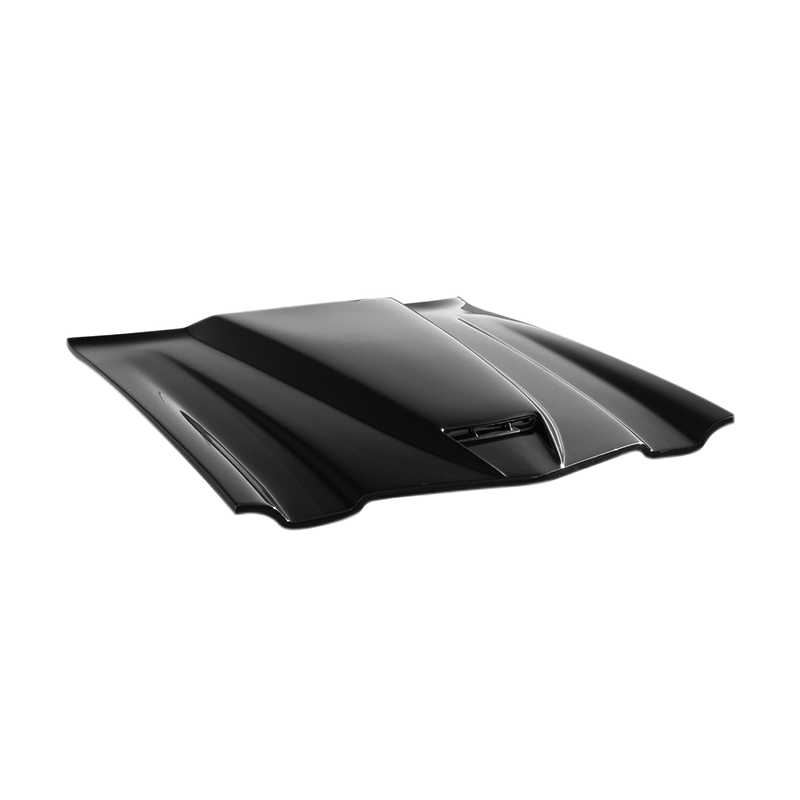

For us, fitment is everything. It doesn’t matter how slick a wheel looks if it doesn’t fit right. However, for many owners of six figure rides, correct fitment is assumed and what really counts is enhancing the appearance of their vehicle with some awesome rims. Because they are custom made and multiple part, three-piece wheels are ideally suited for unique designs and finishes. Each piece can receive a design element and that means each piece can bring a unique contribution to the total design. Outer rims (the lip) can have stepped lips or double stepped lips. Inner rims and cores can support any kind of spoke and cap design from traditional five spoke, to blades, to floating spokes and more. Even the style and placement of bolts can be customized. And colors…the rainbow is your guide. Because each piece can be finished before assembly, multiple finishes are routine.