- FULL DESCRIPTION

-

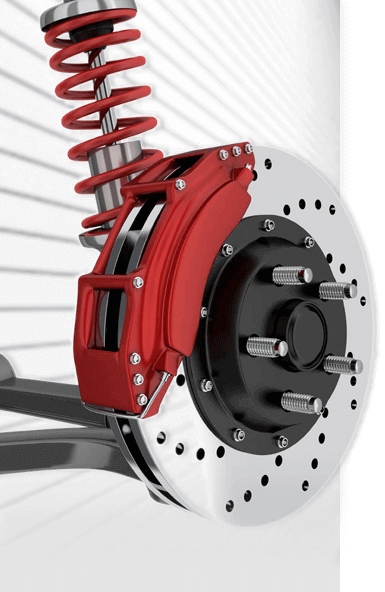

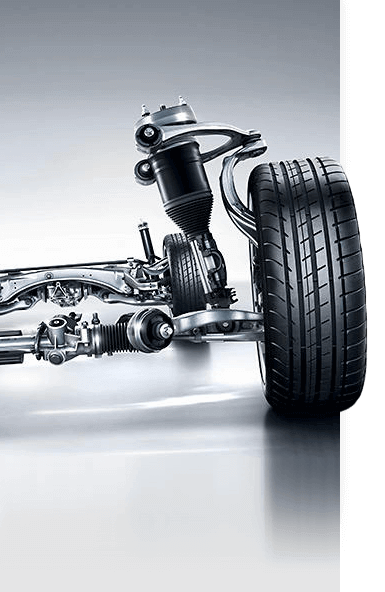

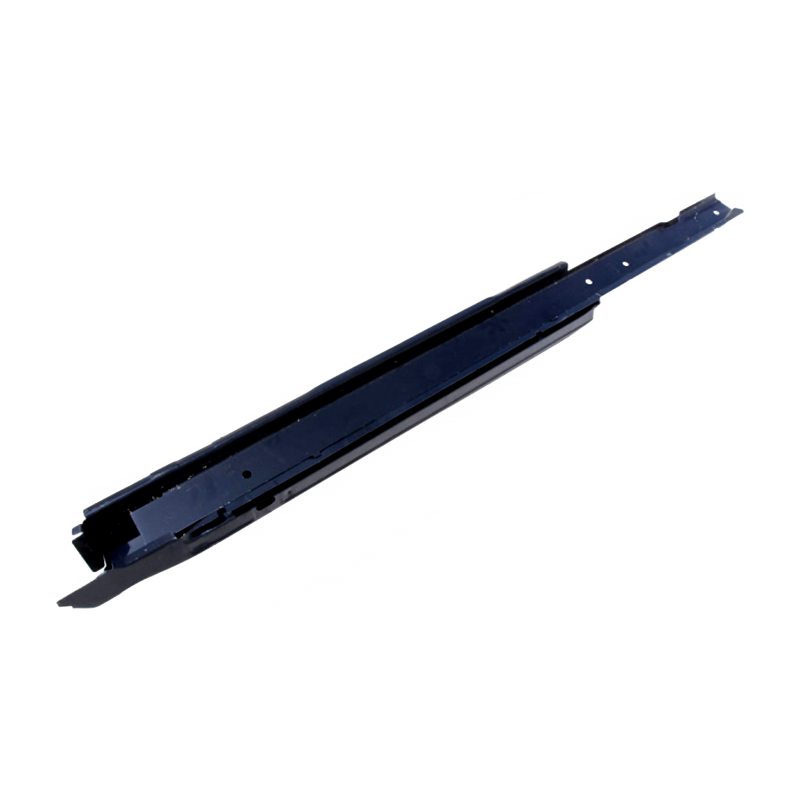

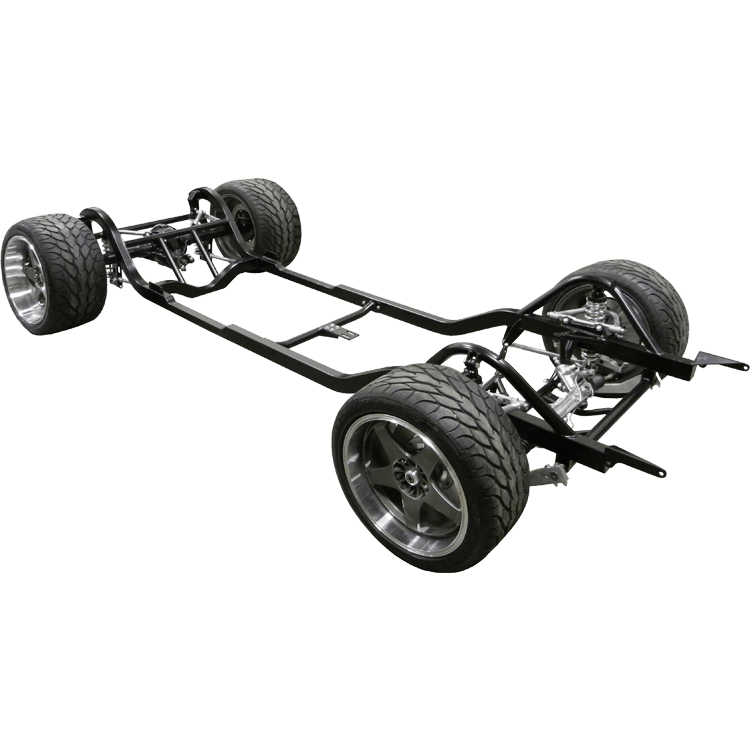

Performance Accessories 3-inch Body Lift Kit PN-5583 raises the vehicle for adding larger diameter tires, without altering the factory suspension system and OEM ride characteristics. The kit includes high pressure fiberglass reinforced nylon lift blocks, 3/16 inch thick laser cut and powder coated front and rear bumper relocation brackets, a CNC machined and zinc plated steering extension, high strength hardware, and extension brackets. A set of urethane wheel-well extensions (Gap-Guards PN-6335) are available separately, and are used to conceal any gaps between the body and frame. This system can be installed in 6-7 hours and comes complete with everything necessary for installation. Benefits: Provides 3-inches of lift without modifying existing suspension components. Allows use of larger diameter tires and factory rims for improved ground clearance. DOES NOT alter the OEM suspension geometry or factory stability control parameters. Maintains the factory smooth ride. Keeps the trucks center of gravity lower than a comparable suspension lift .Features: Fiberglass reinforced nylon body blocks CNC machined & zinc plated steering extension Laser cut and powder coated front and rear bumper relocation brackets Laser cut and zinc plated fittings and brackets High strength hardware included Made in the U.S.A. Made in the U.S.A.

- MANUFACTURER

DESCRIPTION -

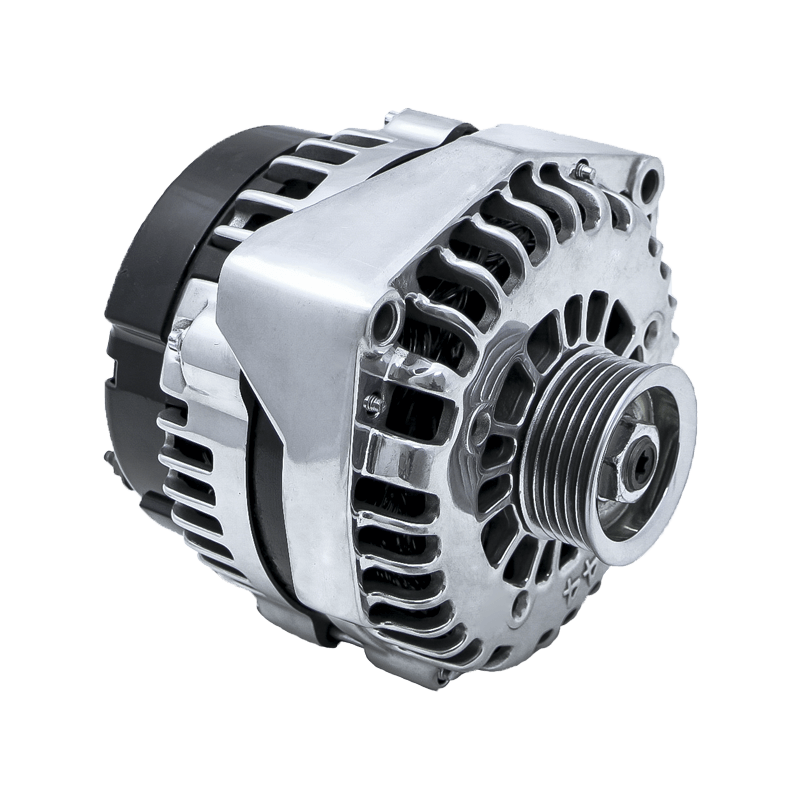

njection Molding Daystar™ produces millions of plastic injection molded parts every year on micro processor controlled Van Dorn molding machines ranging in size from 85 to 400 tons. We are extremely experienced in running elastomeric compounds such as flexible PVC's, thermoplastic polyurethanes, and TPR's. We also run large quantities of other thermoplastic resins. Boots The design and production of elastomeric boots or bellows is a Daystar™ specialty. We have developed proprietary design software, specialized injection molding bases, special purpose robotics, and unique boring and turning tools that enable us to provide the optimum boot solution to our customer at unrivaled tooling and piece part prices. Quality Daystar™ has always met our customers' needs by designing and producing the highest possible quality parts. Since 2000, Daystar has been certified ISO 9001, and we currently hold ISO9001:2008 certification. This demanding certification, recognized worldwide, ensures our customers that the entire process, from design to shipment, is independently verified and documented to meet or exceed our customers' expectations. Cast Polyurethane Daystar™ is a recognized specialist in manufacturing cast polyurethane elastomeric and microcellular foam parts for the automotive industry. We have developed several families of proprietary polymer formulations that give us the ability to match material properties to the specific application at hand. Engineering Engineering excellence is not just a catch phrase at Daystar™ - it is the foundation of our company. Daystar™ engineers can execute all aspects of the design process for part modeling and simulation to multi axis toolpath creation. Toolmaking Daystar™ has been producing high quality injection molds for over 30 years ranging in sophistication from single cavity prototype molds to multicavity molds with hot runners and side actions. Our production facility includes multiple dispensing lines, a clean room for steel preparation for bonding operations, several custom designed automatic parts trimmers, a laboratory for testing part designs and material properties, and most importantly, a skilled team with a proven track record.